Controlling the direction of LED light…

LED’s

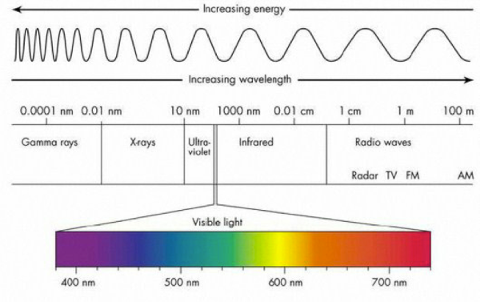

LED stands for Light Emitting Diode. It is a type of semiconductor capable of generating light of different wavelengths depending on materials used. In the past basic colors like red and green where the common colors used as indicator lamps in lots of electronic applications but nowadays there are multi-color and white LED’s and they are being used in lighting applications more and more.

White light

White light does not exist on itself but is a mix of wavelengths (colors). A typical way of creating white light is by using blue LED chips and coating them with fluorescent materials that absorb blue light and emit yellow. The mixture of these two is perceived as white. By choosing the right blue chip and phosphor combinations all whites from cool to warm white can be made. By driving cool and warm white LED’s separately in an application, the whole range of white colors can be created.

Another possibility is to mix red, green and blue (RGB) wavelengths using individual RGB LED’s or multi-color RGB LED’s. The red, green and blue LED’s can be driven separately also allowing the creation of the whole range of cool to warm white, but actually virtually any color, including very saturated ones.

Color temperature

White light is not a single color. All colors close to the so called blackbody curve are called white. The CCT value (Correlated Color Temperature) indicates the type of white. In practice CCT ranges from warm white 2800 K (incandescent light) via neutral white 5000 K (sunlight at noon) to cool white 10000 K (clear blue sky).

Color rendering

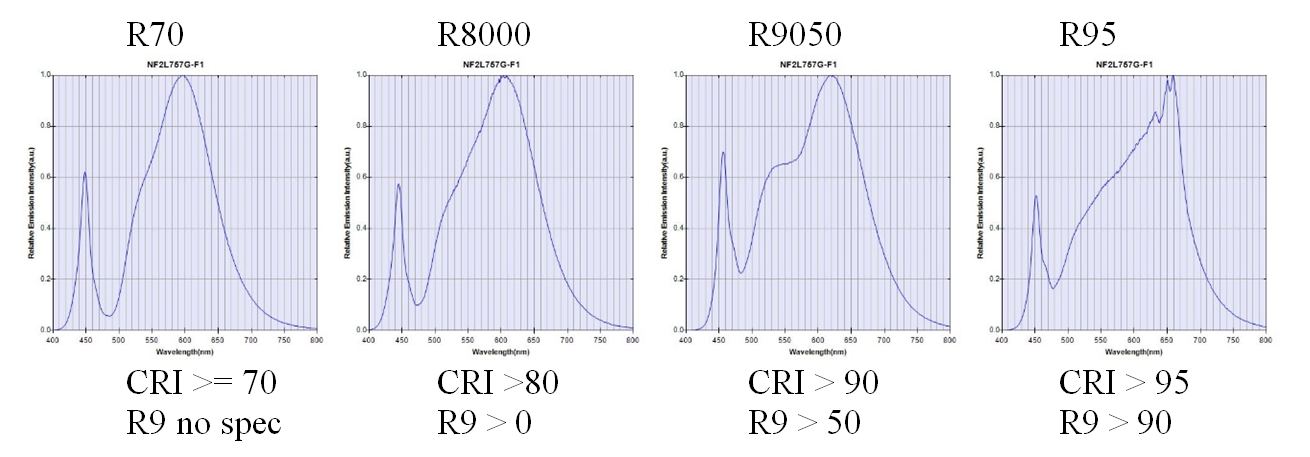

The CRI (Color Rendering Index) of a light source determines how close colors of objects – when lighting them – are matched in comparison with an ideal or natural light source (like the sun). These reference light sources have continuous spectra, meaning that all visible wavelengths are present. Early white LEDs had a very low CRI because they lacked a large part of the spectrum between blue and yellow. By mixing multiple phosphors nowadays high CRI LED’s exist producing light hardly distinguishable from incandescent lamps and TL’s.

The spectra below are typical examples of LED’s with different color rendering. These spectra, from Nichia LED’s NF2757G-F1 (http://www.nichia.co.jp), show clearly that spectra can be constructed to obtain high CRI values.

In addition to the CRI value also the R9 value is mentioned at the example spectra. Saturated red colors are not included in the definition of the CRI. Value R9 is used for that purpose. Many LED light sources cannot reproduce saturated red colors. But, as shown in the last spectrum, it is very well possible with LED lighting to do so.

LED’s with high color rendering properties are less efficient. Actually color rendering is a tradeoff with efficiency.

Although RGB LED’s can also create the full range of white’s, their CRI is rather low because of the gaps in the resulting spectrum between red, green and blue. By using additional colored LED’s like amber and/or cyan these gaps can be reduced, resulting in improved CRI. For the non-white colors that these LED’s can create, the CRI is very low. Actually CRI is not defined for non-white colors.

Controlling the direction of light.

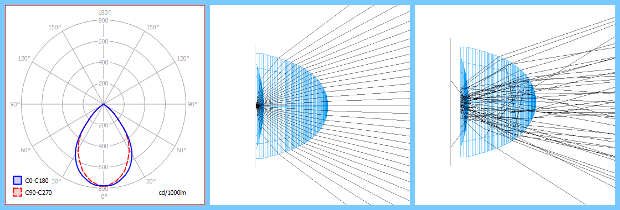

We develop optical systems that control the direction of light coming from the LED chip depending on the required application. High construction sites or hangars have different requirements than for example parking buildings with low heights or sports fields which are outside (low temperatures during winter season and high temperatures in summer) and need even lighting distributions directed only on the field itself. Our lighting solutions, as being used by our customers, take into account issues as blue-yellow color de-mixing (which is a result of some specific type of LED constructions) and beam angle. All effort is being made to reduce glare and make sure you get the light where you want it to be.

Optimized en non-optimized optic (The right one has more yellow inside 😉 ) :

Silicone optics.

Besides the optical systems discussed above, that use thermoplastic materials (PMMA,PC), we also process silicone material to form lenses. To be able to properly guide the light, create better efficiencies and minimize the size of the optics the lens must be as close to the LED as possible. However, LED’s can get significantly hot and even lead to melting of materials used! The primary advantage of silicone materials is their higher resistance to heat allowing for closer mounting to the lens opening a whole new world of possibilities!